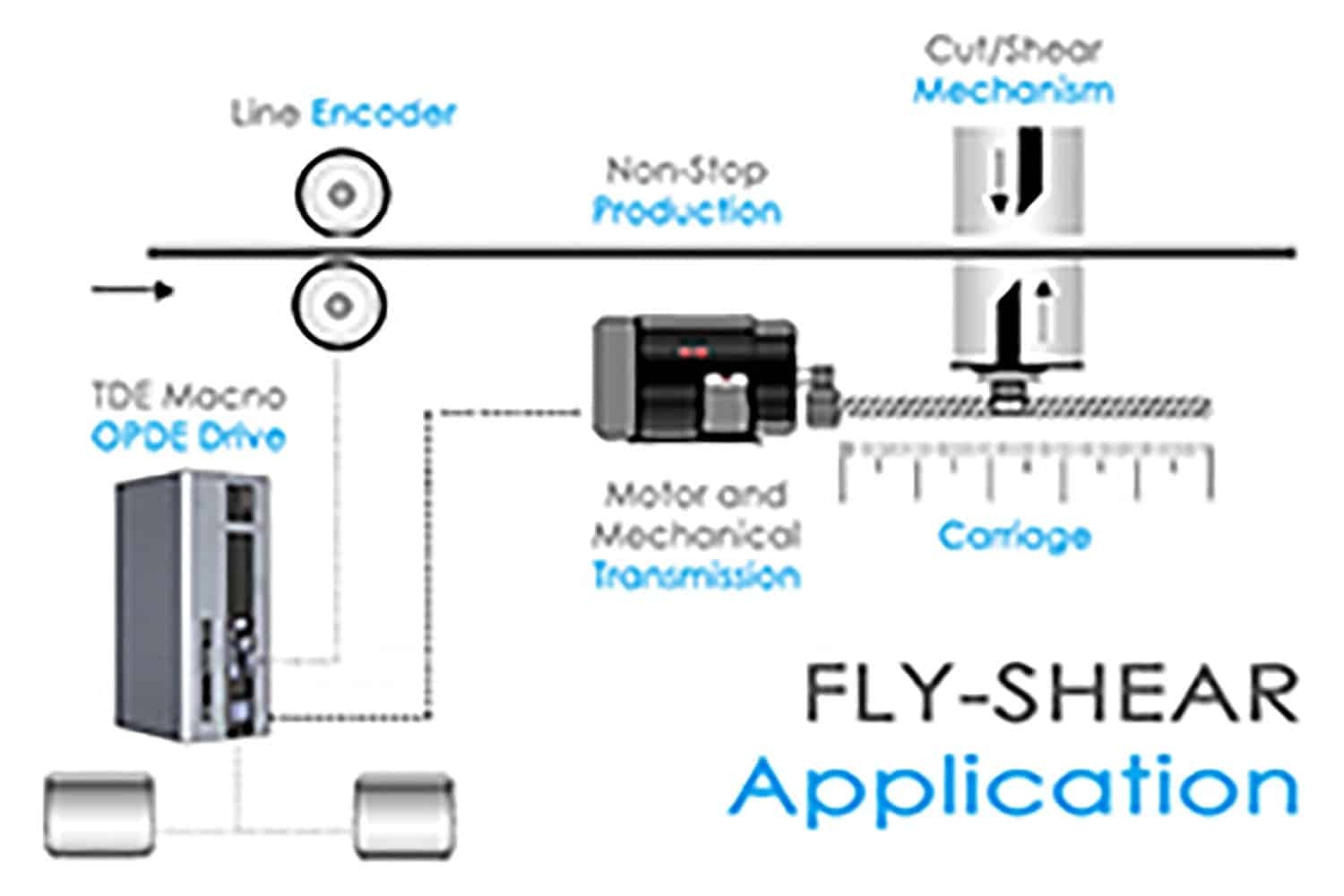

FLY-SHEAR APPLICATION

The flying cut is a drive application for cutting continuous feed material into predefined lengths.

A Shear Knife Mechanism is moved by a timing belt controlled by our OPDE: the drive reads the position and the speed of the material and controls the timing belt movement.

The shear is accelerated to a speed that exactly matches the material speed, then the cutting process starts.

All the movements are defined by S-curves in order to have smooth accelerations and to reduce the wear and tears on components.

Through a Point-to-Point positioning it is also possible to choose between 2 ways of return to the start position:

the shear can return when it completes its cycle and reaches the travel limit or when the cut has taken place.

Applications:

– Cutting

– Sawing

– Punching

– Welding

– Embossing

– Perforating paper, metal and foil webs, as well as wood or plastics